It is a critical raw material for a spray polyurea elastomer. The polyurea elastomer, which is prepared from polyetheramine and isocyanate through high-speed mixing and spraying of special equipment, has excellent physical and chemical performance, such as excellent tensile strength, elongation, abrasion resistance, aging resistance, tear resistance, corrosion resistance etc.; As the terminal amidogen and the isocyanate group can rapidly react and solidify without solvents, the spray polyurea has excellent workability, eco-friendly performance and wide applications. Polyetheramine can be used for primary structure protection of important concretes, steel structure etc. commonly found in high-speed railways, large oil storage tanks, water treatment pools of nuclear power plants, mine tailings ponds, wear-resisting lining of pickups, anticorrosive coatings of sea-crossing bridges, aseptic workshops, high-class floor of hospitals, leakproof and anticorrosion of wastewater treatment pools and of city garbage dumps, internal and external protection for land and submarine oil pipelines, ship deck, wear-resisting coating of screws, temporary parking aprons for aircrafts, stadiums and tracks and so on.

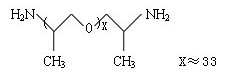

Polyetheramine D-2000 is a poly (propylene oxide) compound mainly terminated by primary amidogen.

The structural formula is as follows:

| Molecular weight Wn | ~2000 |

| Functionality | ~2 |

| Total amine, meq/g | 0.97-1.05 |

| Primary amine,% of total amine | 97 min. |

| Color.pt-Co | 25 max. |

| Water. wt% | 0.2 max. |

APPLICATIONS:

·Key component of spray Polyurea and RIM

·Epoxy curing agent

FEATURES:

·Low viscosity, low color and vapour pressure

·Improves flexibility and peel strength