Mainly used as a new epoxy curing agent. The resin cured by Polyetheramine T-403 has excellent toughness, impact resistance and low temperature tolerance. As its exothermic peak during solidification is low, Polyetheramine T-403 can be used to cast large epoxy resin components. In addition, its low color makes the cured casting body crystal clear. Therefore, Polyetheramine T-403 is widely applied to epoxy composites, epoxy coatings, epoxy electrophoretic coatings, binders, circuit boards, sealants and artworks etc.

Polyetheramine T-403 exhibits high performance especially in strengthening wind turbine composite blade materials. Each blade of an MW-grade wind turbines weighs 5 to 6 tons itself. Coupled with large forces in different directions and temperature variations from -50℃ to 70℃, this sets a very stringent standard for blade materials. Real life applications have shown that proper epoxy resin, cured with a specific Polyetheramine T-403, fully meets the requirement for the blades. So far there are no substitutes in the curing agents of the wind power turbine composite blades.

Polyetheramine T-403 is a kind of engine fuel oil additive with excellent resistance to sedimentation. It can also be applied to surfactants.

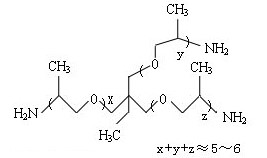

Polyetheramine T-403 is a poly (propylene oxide) compound mainly terminated by primary amidogen.

Structural formula:

| Molecular weight Wn | ~440 |

| Functionality | ~3 |

| Total amine, meq/g | 6.1-6.8 |

| Primary amine,% of total amine | 90 min. |

| Color.pt-Co | 50 max. |

| Water. wt% | 0.2 max. |

APPLICATIONS:

•Epoxy curing agent

•Caulked joint adhesive of polyurethane and a viscosity extender of sealant

•Crosslinking agents in RIM polyurethane and spray polyurea system

FEATURES:

•Low color and vapor pressure

•Completely miscible with a wide variety of solvents, including water